The LINESTAR system 9000 from BAUER is the best irrigation solution for large rectangular fields. In contrast to the pivot, which moves in a circle, linear systems have a central unit that moves linearly across the field together with the tower units. Across the field and back again. A special linear control always keeps the machine on the right track. Perfect alignment and automatic correction of deviations between the towers are possible even on challenging terrain. The water is supplied via hydrants and a supply hose or from a ditch feed. A generator system in the central unit ensures a mobile supply of power. The LINESTAR performs best in long rectangular fields, where it can achieve almost 100% space utilization. It stands out with lower operating costs per hectare compared with other forms of irrigation.

| 2-wheel | 4-wheel | Linestar Basic data |

|---|---|---|

| ● | rigid connections (4 - couplings) | |

| ● | rotary connection | |

| ● | central supply | |

| ● | ● | Double connection - for the use of 2 drag hoses |

| ● | towable design | |

| ● | ● | Span 168LL lengths: 42.3 m to 59.8 m |

| ● | Span 168LL lengths: 42.3 m to 59.8 m | |

| ● | ● | Span - High design |

| ● | ● | Control Unit LINESTAR-PRO |

| ● | ● | Max. recommended system length : 450 m |

| ● | Max. recommended system length: 760 m With central supply | |

| ● | ● | Overhang,Ø133 length: 5,9 to 23,4m |

| ● | ● | end gun |

| ● | ● | Booster pump |

| ● | Pulling device from the overhang | |

| ● | ● | Drag hose 4" (200m 4-wheel, 160m 2-wheel) |

| ● | ● | Drag hose 5" (150m 4-wheel, 110m 2-wheel) |

| ● | Drag hose 6" (110m 4-wheel) | |

| ● | ● | Furrow guidance |

| ● | ● | Cable guidance |

| ● | ● | Burried guidance |

| ● | ● | SMS control unit - option |

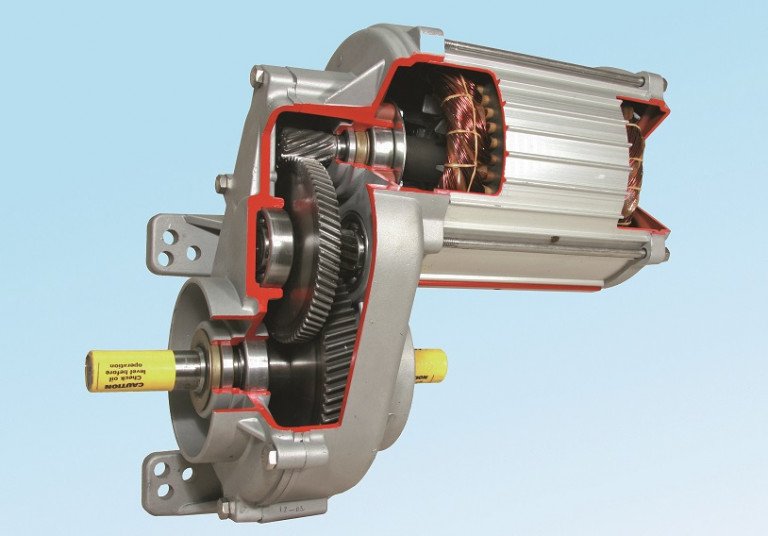

The sturdy drive tower coupling, free from play, with ball and socket perfectly compensates for extreme slopes. Mounted on the outside of the pipe, it does not restrict the cross-section of the mainline pipe, thereby ensuring optimum water flow without pressure loss. The weather, UV and ozone-resistant hose collar facilitates large angles.

BAUER is the only manufacturer to offer a control lever that is mounted directly above the swivel point of the flexible joint. Any torsion in the pipe has no influence on the control; the entire system is kept stress-free. Optimum adjustment of switching brackets with precision bearings of the control cams ensures precise movement transmission. Precise drive tower control system leads to a long product lifespan.

The precision control for all Linestar and Centerliner systems (regardless of the number of spans) and for Centerstar systems with more than 12 drive towers offers utmost accuracy. The angles between the drive towers are transmitted by means of control cables, counter-balancing any torsion in the steel structure.

Tried and trusted sturdy elements for application under the most extreme conditions. Easy-to-use control surface and robust control elements to ensure smooth operation. All of the basic functions for automatic operation are integrated into all of the control centres. A comprehensive range of accessories is available for retrofitting further elements for additional operating functions.

Only standard quality components from well-known manufacturers (Schneider Electric, Schrack, Moeller, etc.) are used in accordance with the strictest VDE standards. The corrosion protection of the switch cabinets has been adapted to tolerate extreme climatic conditions.

The GPS-supported application SmartRain offers new possibilities in irrigation management. No matter where the user is, he is always informed about the current status of his irrigation system and can also remotely control the machine at any time.

Here you will find your right contact person.

Whatsapp Number:

+55 19 99492-5418

Whatsapp link:

Bauer do Brasil